MONDAY, MARCH 11, 2024. BY STAN GRANT, VITICULTURIST.

The basics of vineyard management include taking appropriate actions at the right time and with the proper intensity to achieve the desired viticultural result. These basics provide guidance about what to do, but only partly about how to do them.

The “how” of a vineyard task influences its benefit to a vineyard enterprise. In this regard, a high level of efficiency in task execution enhances the value of the resources and investments involved and thereby, its benefit. For this reason, efficiency is an essential element of sustainable winegrape growing. It is also the focus of this article.

Types of Operational Efficiency

There are three primary types of efficiency in vineyard operations. Probably the most familiar type is physical efficiency, which is the amount of crop produced per unit resource (Figure 1). Measures of physical efficiency include tons of grapes produced per planted acre, tons of grapes per man-hour of labor, tons of grapes per acre inches of applied water, and tons of grapes per pound of applied fertilizer nutrients. Physical efficiency typically increases as yield increases and it decreases when input costs are unusually high, materials are wasted, and the crop is left unharvested in the field.

Figure 1. Fruit yield per the amount of an applied resource is the general formula for physical efficiency. (Photo source: Progressive Viticulture©).

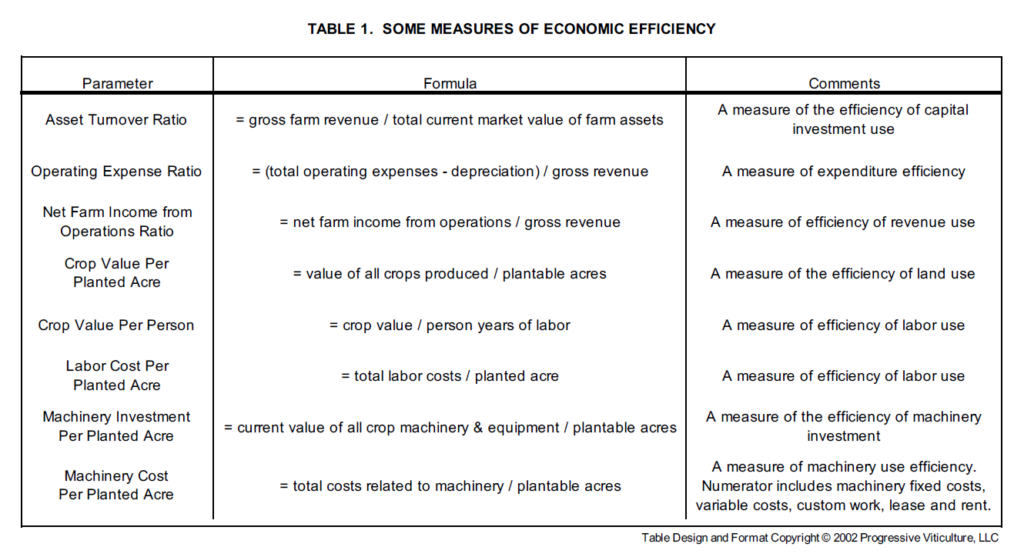

The second efficiency type is economic efficiency. Economic efficiency is measured in dollars or as a rate of capital use. The crop value per planted acre (land efficiency), the machinery cost per planted acre (machinery efficiency), and the net farm income per unit gross revenue (income efficiency) are measures of economic efficiency (Table 1). These parameters underscore the significance of crop value (the product of yield and price per ton), prudent purchases, and return on investments.

The third type of vineyard efficiency does not have a commonly accepted name, but we will refer to it as viticultural efficiency. It represents the amount of fruit produced per unit of vine growth or growth capacity. The crop load, which is the amount of crop per unit leaf area, is the best-known parameter of viticultural efficiency. The yield per node retained at pruning and the yield to pruning weight ratio (a.k.a. Ravez Index) are similar, but less precise parameters. Another is the coefficient of commercial efficiency, which is the yield divided by the total annual growth including fruit. All of these quantities are measures of balance between reproductive growth (fruit) and vegetative growth (foliage). They reflect the effectiveness of vineyard resource use and the degree of vine stress, which if extreme, diminishes vineyard health and economic life span.

Designing and Developing Vineyards for Efficiency

The future fruit production efficiency of any new vineyard project depends upon actions taken to create a favorable root zone across the vineyard site prior to planting. Such actions must suit soil conditions. They may include grading, amending, deep tillage, tile drainage installation, and berm making.

An efficient vineyard also requires a design that achieves the greatest fruit value with the lowest resource costs. Land is usually the costliest resource. Therefore, the most efficient vineyard design has the variety, rootstock, and spacing-training-trellis-pruning system that most easily converts the natural assets of the site (soil and climate) into the greatest fruit value (Figure 2).

Figure 2. A canopy with a thin layer of leaves extending across a vineyard is viticulturally efficient. (Photo source: Progressive Viticulture©).

Labor is usually the highest input cost for operating vineyards (Figure 3). For this reason, efficient vineyard designs accommodate effective and economical mechanization in place of labor as much as possible. Mechanization, however, can be less efficient than labor when the machinery is too expensive, too specialized, or used on too few acres. In these instances, sharing equipment ownership with another grape grower or hiring a customer operator can be the most efficient option for a vineyard task.

Figure 3. Hand labor is among the highest input costs for wine grape vineyards. (Photo source: Progressive Viticulture©)

Lastly, efficient vineyard designs incorporate long rows that minimize the number of turns for crews and equipment, which are non-productive. Where feasible, align vine and tractor rows of adjacent blocks to allow machinery to pass through both blocks while performing a task, such as mowing, before turning. Also, make headlands wide enough (at least 32 feet wide) to allow the turning of large vineyard machinery, such as mechanical harvesters.

Operating Vineyards for Efficiency

In established vineyards, efficiency is a function of resource efficacy and the rate, timing, and placement of the resource. Obviously, it is inefficient to apply too little of a resource because it will fail to produce the desired result and it is inefficient to apply too much of a resource because it is wasteful.

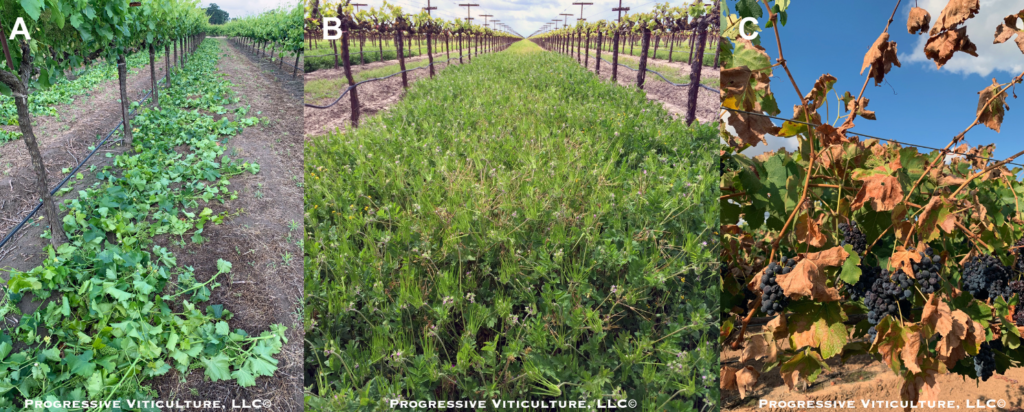

What is sometimes less obvious is the importance of application timing. In short – it is always more efficient to apply a resource at the proper time. Supporting examples abound. Thinning 6 to 10-inch shoots requires less labor and conserves more internal vine resources than thinning longer shoots (Figure 4A). Control of small weeds requires less time and energy and conserves more soil water and mineral nutrients than controlling larger weeds, especially those that have set seeds (Figure 4B). Importantly, applying water when vines require it is more efficient than dealing with the detrimental effects of severe water stress (Figure 4C). These examples show that proper timing enhances efficiency through reductions in application costs and avoidance of costly side effects. Precision application techniques, which restrict resource applications to the part of the vineyard in need, further enhance efficiency.

Figure 4. Proper timing of vineyard tasks is critical to their efficiency, including shoot thinning (A), weed control (B), and irrigations (C). (Photo source: Progressive Viticulture©)

Maintenance and calibration are also critical to the efficiency of vineyard operations. Clearly, well-maintained vineyard machinery is more energy efficient and less prone to breakdowns than poorly maintained machinery. At the same time, proper calibration is required to ensure the targeted application rate, including those for broadcast, banded and sprayed applied materials.

Maintenance also applies to many other aspects of vineyard operations beyond machinery. For example, maintenance of highly skilled labor through training can diminish the number of man-hours per acre and lost time due to accidents and injuries. Well-maintained drip irrigation systems enhance the distribution uniformity and efficacy of applied water and fertilizers (Figure 5). Root zones maintained through amending, cover cropping, and careful tillage promote water and mineral nutrient use efficiency. Grapevines maintained for uniformity of form through careful pruning make for efficient canopy and crop management.

Figure 5. Drip system performance depends upon regular maintenance. (Photo source: Progressive Viticulture©)

The final, but most basic aspect of vineyard efficiency is common sense management. Select a tractor with a horsepower rating that closely matches the job requirement, assure proper tire slippage, run at an appropriate speed, minimize turns, and where possible, minimize passes by treating more than one row at a time or treating only part of the vineyard. Select material resources with the greatest effect per dollar and apply them when conditions are likely to maximize their efficacy. Utilize input application methods and models such as regulated deficit irrigation (RDI) schedules based on evapotranspiration (ET) or soil moisture measurements, balanced mineral nutrient management methods, disease forecasting models, and insect developmental models (e.g., OLR). Avoid leaving unharvested crops in the vineyard. And of course, work to maximize revenues through the highest attainable crop value.

Conclusions

Efforts to fine-tune vineyards focus on the efficient use of assets, capital, and natural and applied resources for optimizing vine growth balance and yield, crop value, and return on investment. In addition to performing pertinent vineyard tasks at the most appropriate time and with the proper intensity, efficiency efforts require careful task execution. Further, to ensure a vineyard business advances and remains profitable, such efforts must evolve and improve over time.

A version of this article was originally published in the Mid Valley Agricultural Services February 2006 newsletter and was updated for this blog post.

Further Reading

Battandy, M. Reducing vineyard water use: mechanisms, strategies, and limitations. Grape Notes. UC Cooperative Extension, San Luis Obispo, and Santa Barbara Counties. September 2013.

Beierlein, JG, Schneeberger, KC, and Osburn, DD. Principles of agribusiness management. Waveland Press, Long Grove, IL. 2008.

Bruulsema, T. Efficiency as a metric of sustainable crop production. Plant Nutrition Today. International Plant Health Institute. Peachtree Corners, GA. Summer 2015.

Grant, S. Fertilizer efficiency for wine grape vineyards. Practical Winery and Vineyard. 28 (1): 35-41. March/April 2006.

Grant, S. On the nature of vineyards and vineyard management. Lodi Winegrape Commission Coffee Shop Posting (www.lodigrowers.com). March 06, 2016.

Grant, S. The basic elements of successful vineyard management. Lodi Winegrape Commission Coffee Shop Posting (www.lodigrowers.com). January 26, 2018.

Grant, S. Quantity, intensity, and timing in the management of vineyard resources. Lodi Winegrape Commission Coffee Shop. (www.lodigrowers.com). February 11, 2019.

Grant, S. Comprehensive vineyard water management. Lodi Winegrape Commission Coffee Shop. (www.lodigrowers.com). August 18, 2015.

Grant, S. Managing vineyard mineral nutrient efficiency beyond the 4 R’s. Wines and Vines. April, 2016. pp. 77-78.

Grant, S. Managing mechanized vineyard equipment for maximum efficiency. Lodi Winegrape Commission Coffee Shop. (www.lodigrowers.com). December 15, 2017.

Grant, S. Vineyard longevity. Lodi Winegrape Commission Coffee Shop. (www.lodigrowers.com). November 09, 2017.

Grant, S. Vineyard design and management for maximum efficiency. Lodi Winegrape Commission Coffee Shop. (www.lodigrowers.com). February 22, 2018.

Grant, S. The seasonality of vineyard mineral nutrient management. Lodi Winegrape Commission Coffee Shop. (www.lodigrowers.com). May 24, 2021.

Grant, S. Monitoring vineyard business economics. Lodi Winegrape Commission Coffee Shop. (www.lodigrowers.com). December 12, 2022.

Grant, S. There is more to vineyard floors. Lodi Winegrape Commission Coffee Shop. (www.lodigrowers.com). March 28, 2022.

Grant, S. Mineral nutrient management methods: a comparison considering effectiveness and efficiency. Wine Business Monthly. May 2022.

Grant, S. Deep tillage for preparing and maintaining vineyards root zones. Lodi Winegrape Commission Coffee Shop. (www.lodigrowers.com). October 17, 2022.

Kay, RD, and Edwards, WM. Farm Management. McGraw-Hill, New York. 1994.

Levin, AD, Matthews, MA, and Williams, LE. Effect of preveraison water deficits on the yield components of 15 winegrape cultivars. Am. J. Enol. Vitic. 71, 208-221. 2020.

Reetz, HF. Fertilizers and their efficient use. International Fertilizer Industry Association, Paris. 2016.

Ruehr, T. Fluids the key to nutrient efficiencies in irrigation management. Fluid Journal. Fluid Fertilizer Foundation, Fertilizer Institute, Arlington, VA. 2008.

Ohmart, CP, Storm, CP, and Matthiasson, SK (Eds.). Lodi Winegrower’s Workbook, 2nd Ed. Lodi Winegrape Commission. 2008. pp. 187-267.

Have something interesting to say? Consider writing a guest blog article!

To subscribe to the Coffee Shop Blog, send an email to stephanie@lodiwine.com with the subject “blog subscribe.”

To join the Lodi Growers email list, send an email to stephanie@lodiwine.com with the subject “grower email subscribe.”

To receive Lodi Grower news and event promotions by mail, send your contact information to stephanie@lodiwine.com or call 209.367.4727.

For more information on the wines of Lodi, visit the Lodi Winegrape Commission’s consumer website, lodiwine.com.

For more information on the LODI RULES Sustainable Winegrowing Program, visit lodigrowers.com/standards or lodirules.org.